SpindlePro

![]()

1. Expert Spindle Design System (ESDS):

This SpindlePro module is used for the initial design of spindles. ESDS is based on the efficient utilization of past design experience, the laws of machine design, dynamics and metal cutting mechanics.

The expert system leads to automatic generation of spindle configuration which includes drive shaft, motor type and size, transmission mechanism between the motor and shaft, bearing types and tool holder style. The bearing locations are optimized under the constraints of chatter vibration free cutting conditions.

SpindlePro ESDS Module has the following features:

- According to the cutting conditions, such as, tool geometry, work-piece material, cutting speeds, depth of cut, etc. The required torque, power and maximum motor speed are automatically predicted.

- Has automatic selection of spindle and transmission type

- Allows selection of lubrication

- Optimizes bearing locations

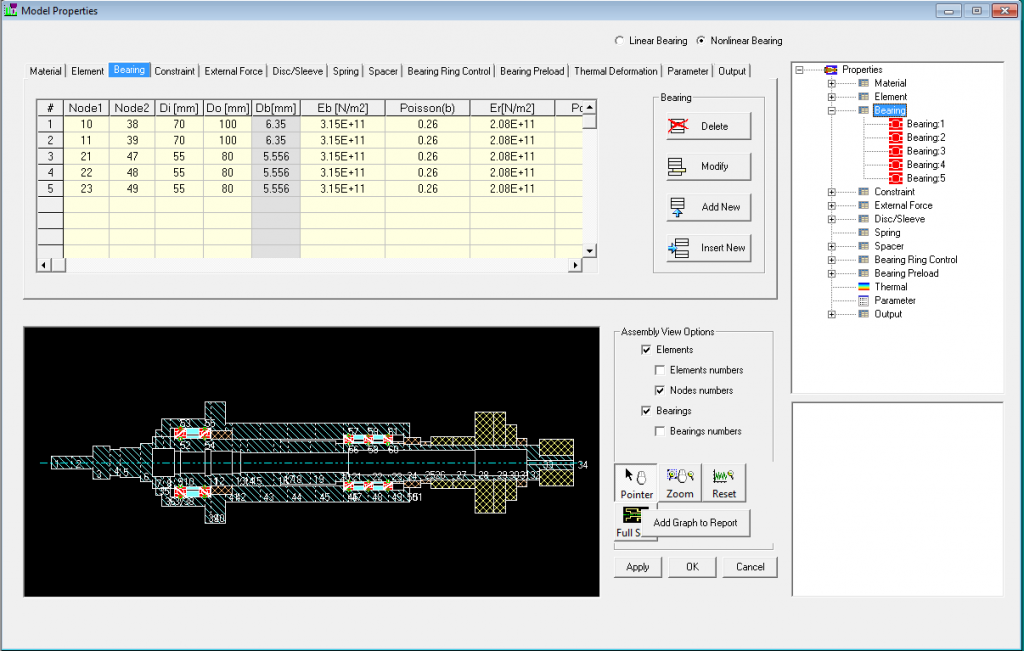

2. Spindle Analysis Module:

This SpindlePro module is a finite element software that is used for performance analysis and optimization of the spindles. It allows to analyze the static and dynamic response of machine tool spindles.

The rotating effects from both spindle shaft and bearings are considered in the model. Timoshenko beam theory is used in the FE model, which includes axial, bending and torsional behavior of the spindle system. The nonlinear bearing model is used to include effects due to preloads and spindle speeds.

SpindlePro Analysis Module has the following features:

- Deflection at any location of the spindle, reaction forces and moments at bearing and housing supports can be predicted under any static forces

- Has damped and undamped modal analysis. The natural frequencies and mode shapes are sorted according to axial, torsional and bending. The user can assign modal damping ratios for each mode from their experience and data base.

- Has fast and user friendly interface to build the spindle model

- Performs Frequency Response Function (FRF) analysis

- Includes rotating effects on bearings and natural frequencies

- Predicts bearing forces undercutting loads

- Displays history of displacement, velocity and acceleration under dynamic forces

- Has user friendly post-processor