MACHpro: THE VIRTUAL MACHINING SYSTEM

![]()

Overview

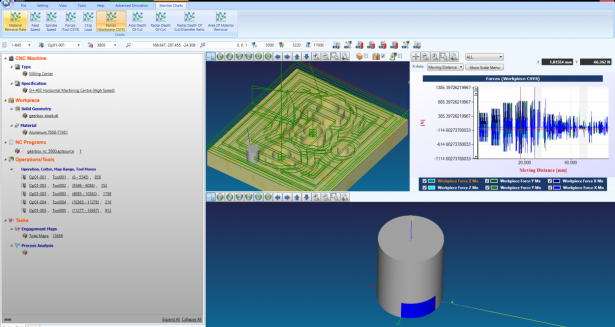

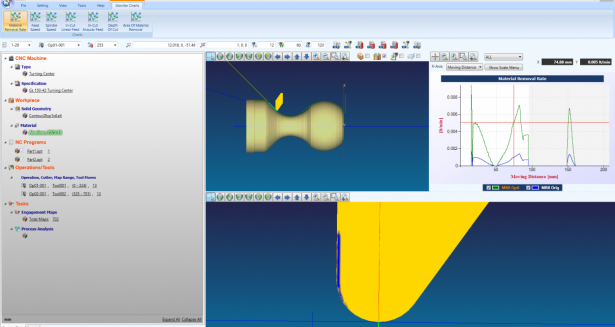

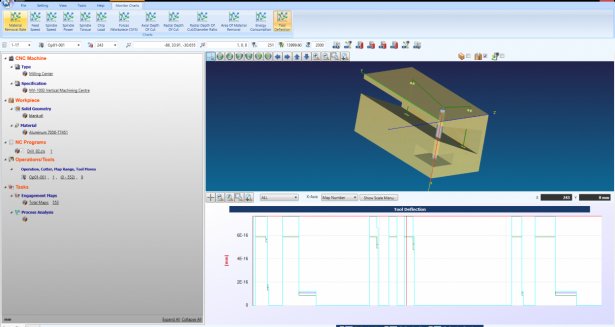

MACHPRO™ is the most advanced process simulation and NC program optimization software. It enables engineers to visualize and simulate real-world performance of machining operations early in the process planning stage. Unlike competitor software, we do not simply look at geometry calculations to optimize programs; we look at the physics involved in machining process, which include machine drives, the cnc, and geometries involved. Since MACHpro covers aspects from the entire machine tool, MACHpro™ is the most accurate machining optimization software. MACHpro is the only NC program optimization software which can simulate machining vibrations and true cycle time within 80% accuracy.

It takes only three simple steps to set up MACHpro™ to analyze and optimize tool paths:

- User inputs stock geometry as a CAD model, tool path life and various physical limits, and selects material workpiece from the database.

- Tool path is executed by MACHpro™ to obtain the final part. Software collects cutter workpiece contact information along the tool path as the part is updated.

- Using cutter workpiece contact information, MACHpro™ virtually analyzes the entire machining process and detects NC blocks that violate user-defined limits of the process.

Features:

- Production time and costs are reduced

- Minimum cycle time

- Quality increased

- Untapped productivity opportunities within existing equipment, tooling and machining process, increased

Applications:

- Flexibility to automatically optimize and

improve critical processes prior to actual machining process - MACHpro™ is fully developed and available in three modules: MILL, TURN, and DRILL

- Machining failures are caught and necessary adjustments are automatically made