Introducing the New CutPro 13

CutPro version 13 brings numerous new features and greater optimization power to harness in your CNC shop. Our latest release features three new toolboxes, updated Tap Testing & Modal Analysis modules, tool material simulation, and more! If you are under a valid support and maintenance plan, you can now automatically update upon launching CutPro.

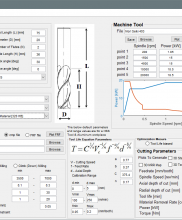

Machining Wizard

For our Milling module, we’ve introduced Machining Wizard as a way to easily optimize cutting conditions. The wizard takes in your tool geometry, machine power characteristics, workpiece material, tool flexibility (CMP or FRF files), and cutting constraints. The wizard determines your tool life, optimized cutting and power parameters for your milling operation. You can also use these parameters to input into a CutPro milling simulation workspace, see the process states (force, torque, power, surface profile, etc.) in detail and achieve a greater understanding of the corresponding machining operation.

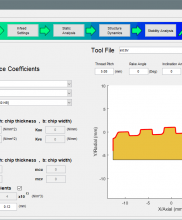

Threading Toolbox

The threading toolbox allows you to simulate and optimize threading operations. You can optimize your infeed settings, perform static analysis on thread depth on numerous factors, import FRF’s to analyze stability, and perform a time-based simulation to determine surface location errors. The toolbox navigated by a step-by-step procedure, the first step being entering in your workpiece and threading insert (tool) settings. Cutting force coefficients can be automatically used from our library of materials or manually entered either as a linear model or Kienzle model. You can choose from numerous infeed methods or an arbitrary flank in the infeed settings. Based on the entered constraints, the number of passes and spindle RPM, you can optimize your infeed settings. In static analysis, you can plot thread depth or the number of passes against forces, torque, power, length of the cutting edge or chip area. Cuts and chips can also be viewed graphically, per pass. In the structure dynamics page, you can import an FRF from Tap Testing and then view your results for stability analysis or time simulation plots.

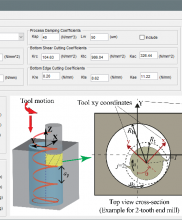

Orbital Drilling Toolbox

Utilize this efficient drilling technique and optimize it even further with our Orbital Drilling Toolbox. Using this toolbox you can simulate orbital drilling operations similar to drilling simulations in CutPro. The toolbox can simulate forces, vibration and surface errors, discrete time chatter, as well as perform a Nyquist check. Side shear and side edge cutting coefficients can be manually entered or applied from our material database. Process damping, bottom shear and bottom edge cutting coefficients are entered by the user. Machine dynamics are then taken for X and Y axes, which consist of frequency, damping, stiffness and mode shape. You can then set your tool geometry, and simulation settings for rotation, spindle speed, hole pitch, and frequency.

New Modal Analysis and Tap Testing Modules

Our Modal Analysis and Tap Testing modules have now been refreshed with a new user interface. The new interfaces in Tap Testing (formerly MalTF), and Modal Analysis are now complimentary to CutPro Machining Simulation; a complete overhaul of the interface provides a more consistent, modern and user-friendly experience. File connectivity between applications has improved with the use of workspace templates. This allows for an easier one-click import process of all your measurements, including axis information, into CutPro.

Tool Material Simulation

Milling simulations are now capable of also simulating the physics behind your cutting tool’s material as well. By being able to simulate forces both on the workpiece and the tool itself, you’re able to get more accurate data, leading to even greater optimization in your shop. We have included two common materials: High Speed Steel (HSS) and Carbide. Users may also define their own tool materials in the new Cutter Material Manager.

Usability Improvements

CutPro is now available in the French language and adheres to applicable regional formatting. As with every CutPro update, bug fixes, usability improvements and user-requested features and fixes are also included. If you have a request or issue, please feel free to create a ticket in our Helpdesk system.