CUTPRO: Milling Simulator Module

The CutPro® Milling Module is highly accurate, and the most comprehensive milling simulator software to achieve the highest material removal rates for NC programming and assists in troubleshooting of milling operations.

The CutPro® Milling Module is highly accurate, and the most comprehensive milling simulator software to achieve the highest material removal rates for NC programming and assists in troubleshooting of milling operations.

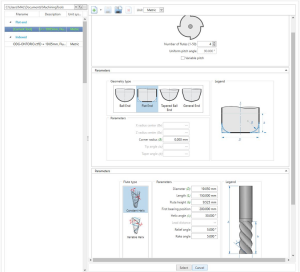

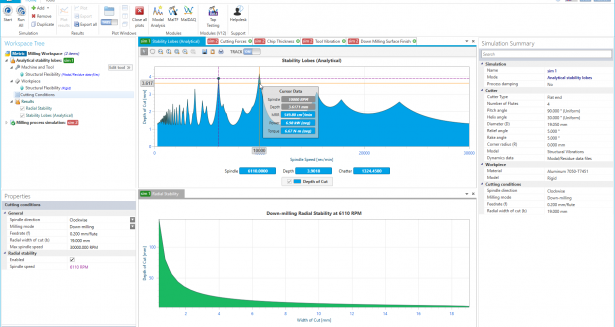

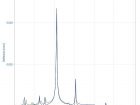

To get started, you enter the basic parameters of the tool geometry, tap test measurement and/or its modal analysis parameters, and select your work material from our material database. Milling stability charts are then calculated which indicate chatter-free depth of cut, the width of cut and speeds.

– click image to enlarge –

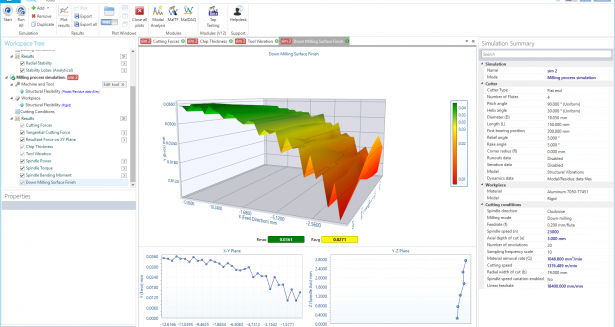

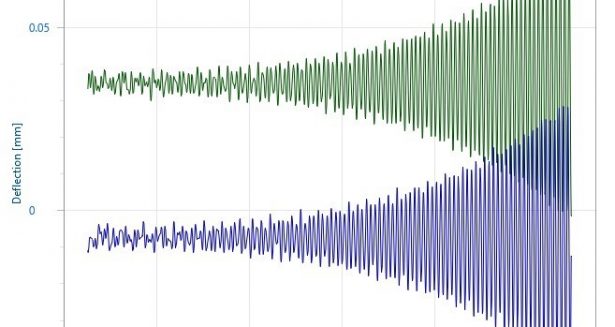

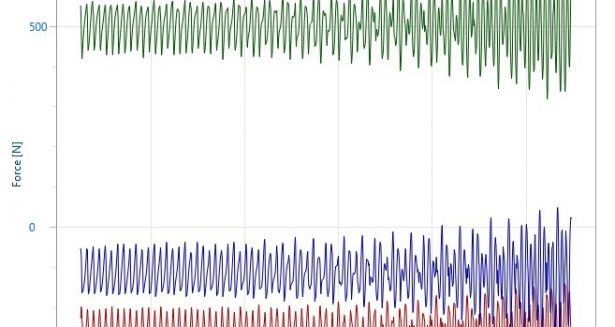

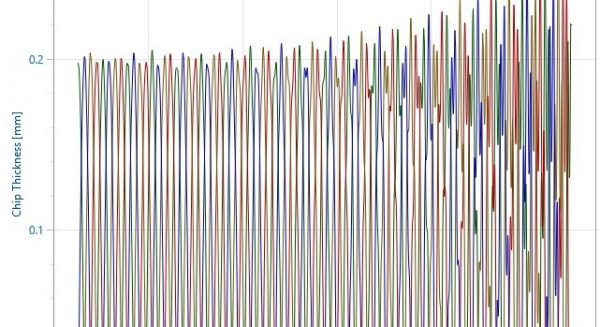

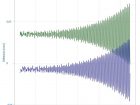

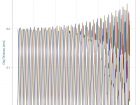

The planner selects the best cutting condition from the stability chart and simulates the material removal rate, chip thickness history, forces, torque, power, vibration amplitudes and their frequencies, surface errors, and load on the bearings. The planner can conduct a “virtual milling test” with CUTPRO. If the conditions are acceptable, the planner may verify them on a simple – straight cutting test for a short cutting test. NC programmer uses the optimally selected best cutting parameters to achieve maximum material removal rate without chatter while obtaining good surface finish and longer tool life.

The Milling Module has five simulation models, which as a package, contain the following features:

- Simulates regular cylindrical endmills, variable pitch cutters, ball endmills, indexable cutters, serrated cutters and endmills with any user-defined geometry and run-outs.

- Has over 200 work materials in the database including Waspaloy, Inconel, Aluminum/Titanium alloys, Steels, cast iron and wood materials. We add new materials periodically, and alternatively, you can add your own materials.

- Accepts dynamic parameters of the machine tool and/or workpiece manually by the user or in a variety of formats (i.e. frf, cmp files) created in CutPro or other commercial modal analysis software packages.

- Has a tool builder allowing you to pre-define existing tools and tool geometries, which can then be used in any simulation.

Milling Simulator Outputs

- Stability charts indicating chatter free speed, axial and radial depths of cut

- Time domain simulation of stability charts

Time Domain Simulation of Milling Operation with following predictions:

- Cutting forces in three directions (XYZ)

- Chip thickness history for each tooth

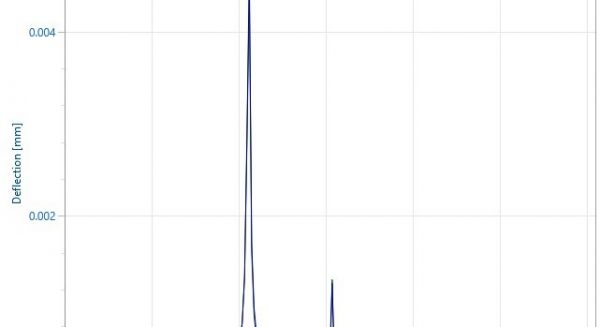

- Vibration amplitudes and frequencies

- Spindle power and torque

- Bending moment on spindle bearing

- Up-milling and down-milling surface finish

- Surface generation and tool vibration animation